Ourungiyarmu ta Ma'aikatan ƙarfe da Injiniyoyi za su tabbatar da cewa kuna da cikakken kwarin gwiwar samfurin da aka kawo.

Binciken mu da dakunan gwaje-gwajen mu suna ba da Metallographic, Mechanical, Dimensional, Chemical, da sauransu.

Zamu tsara tsarin Dubawa da gwaji don biyan bukatunku. Shirye-shiryenmu na Inganci sun kasance daga gwaji na yau da kullun zuwa cikakkun bayanan tabbaci da kuma ganowa.

Muna ba da cikakkun ɗakunan gwaji na hallakaswa da marasa lalacewa gami da:

1. Co-Ordinate Mizanin Injin CMM

2. Radiography

3. Binciken Magunguna

4. Binciken Bincike na Mutuwa

5. Nazarin Kayan Gwajin Kwarewa

6. Gwajin Tensile

7. Gwajin Matsawa

8. Gwajin Bend

9. Gwajin taurin kai

10. Metallography

Nazarin Abubuwan Cutar Chemical

Bayan an narkar da albarkatun kasa cikin narkakken karfe. Muna amfani da awo don gwada kayan narkakken karfe kafin jefawa don tabbatar samfuran suna da ingantaccen karfe.

Girman Girma

Gwajin girma yana dogara ne akan zane don auna ko girman simintin gyare-gyare yana cikin kewayon haƙuri, don gano kuskuren fasali da girma. Kari kan haka, ya kamata a duba daidaiton aikin sarrafa bayanai, rarraba alawus din kayan masarufi da kaurin bango.

Binciken Magungunan Magnetic (MPI)

MPI tsari ne na gwaji mara lalacewa (NDT) don gano farfajiyar ƙasa da ƙarancin katsewar abubuwa a cikin abubuwa masu ƙirar ƙarfe kamar ƙarfe, nickel, cobalt, da wasu abubuwan allo. Tsarin yana sanya filin maganaɗisu a cikin sashin. Za'a iya maginyan yanki ta magnetization kai tsaye ko kai tsaye. Magnetization kai tsaye yana faruwa yayin da wutar lantarki ta wuce ta cikin abin gwajin kuma an sami magnetic fili a cikin kayan. Magnetization na kai tsaye yana faruwa yayin da ba a ratsa maɓallin lantarki ta hanyar abin gwajin, amma ana amfani da filin magnetic daga wani waje. Lines na magnetic na karfi suna daidai da jagorancin wutar lantarki, wanda yana iya zama yana canzawa na yanzu (AC) ko wani nau'i na halin yanzu (DC) (gyara AC).

Gwajin Ultrasonic (UT)

UT dangi ne na fasahohin gwaji marasa halakarwa bisa yaduwar raƙuman ultrasonic a cikin abu ko kayan da aka gwada. A mafi yawan aikace-aikacen UT na yau da kullun, gajeren gajeren gajere na raƙuman ruwa tare da mitar cibiyar daga 0.1-15 MHz, kuma lokaci-lokaci har zuwa 50 MHz, ana watsa su cikin kayan don gano aibun ciki ko halayyar kayan. Misali na yau da kullun shine ƙarancin kaurin ultrasonic, wanda ke gwada kaurin abun gwajin, misali, don saka idanu lalata bututu.

Gwajin taurin

Hardness shine ikon kayan aiki don tsayayya da matsi na abubuwa masu wahala zuwa cikin saman su. Dangane da hanyoyin gwaji daban-daban da kewayon daidaitawa, ana iya raba sassan taurin zuwa taurin Brinell, taurin Vickers, Rockwell taurin, micro Vickers taurin, da dai sauransu raka'a daban-daban suna da hanyoyin gwaji daban, wadanda suka dace da kayan daban ko lokuta tare halaye daban-daban.

Gwajin rediyo (RT)

(RT ko X-ray ko Gamma ray) hanya ce ta rashin lalacewa (NDT) wacce ke bincika ƙimar samfurin. Radiography (X-ray) yana amfani da hasken rana da gamma-ray don samar da hoton samfurin, wanda ke nuna duk wani canje-canje a kauri, lahani (na ciki da na waje), da kuma bayanan taron don tabbatar da ingancin aiki.

Gwajin Kayan Inji

Kamfaninmu sanye take da tan 200 da kuma tan 10 mai ƙwanƙwasa linzami. Ana iya amfani dashi don gwada kayan aikin inji na wasu samfuran musamman.

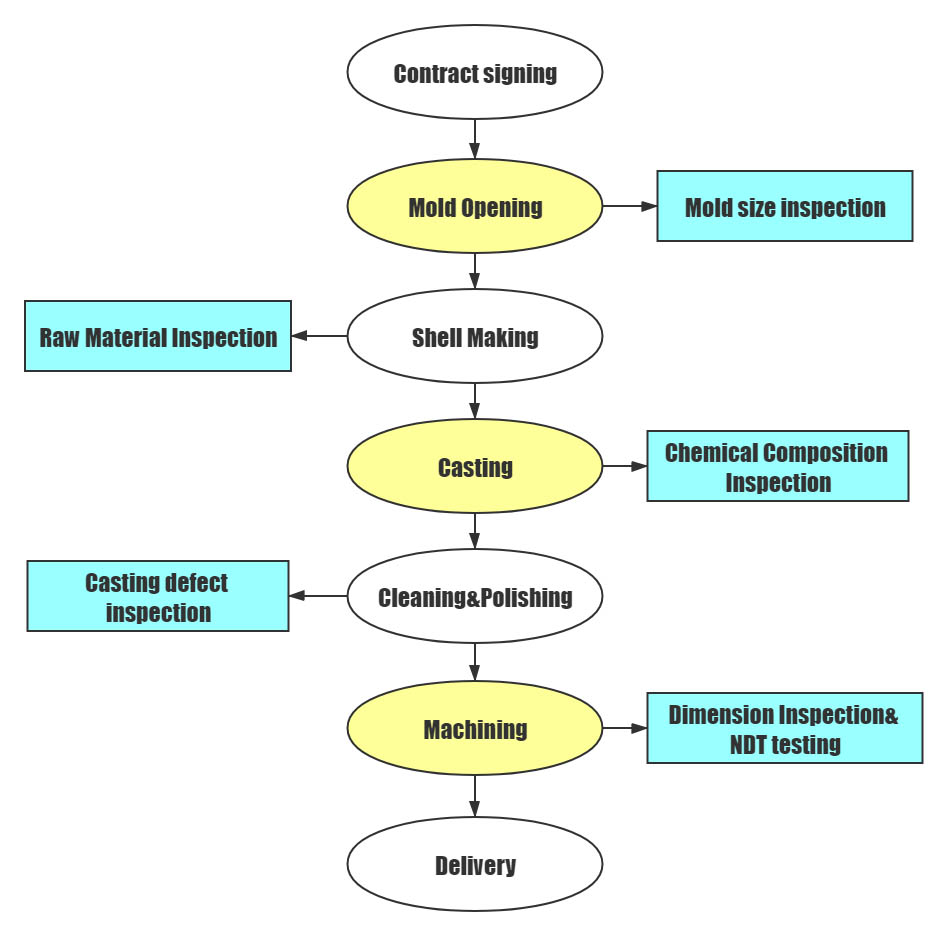

Chart Flow Flow

Kyakkyawan inganci, ƙarancin sifili shine burin da muke bi koyaushe. Tabbatar da kwastomomi shine motsawar ci gabanmu. Bayan fuskantar sama da shekaru goma na kasuwancin duniya, mun sami ci gaba sosai game da kula da ingancin 'yan wasa. A cikin 'yan shekarun nan, mun karu da kayan aikin gwaji masu yawa kamar su 200/10 Tons Tensile inji, Ultrasonic kayan aikin gwaji, Magnetic barbashi kayan aiki, X-ray flaw detection kayan aiki, Masu binciken sinadarai biyu, Mai gwajin taurin Rockwell da sauransu .