Sanya sandunan karafan karfe, sanya sassan sharar gida zuwa wutar makera

1. Fitar tsari: Shell mold daidaici da simintin gyaran kafa

2. Karfe sa: GX130CrSi29 (1.4777) (Hakanan yana iya zama azaman buƙatarku)

3. Haƙurin ofaramar simintin gyare-gyare: DIN EN ISO 8062-3 saitin DCTG8

4. Haƙurin Geometrical na simintin gyare-gyare: DIN EN ISO 8062 - saitin GCTG 5

5. Aikace-aikace: Sharar tsirrai masu tsire-tsire.

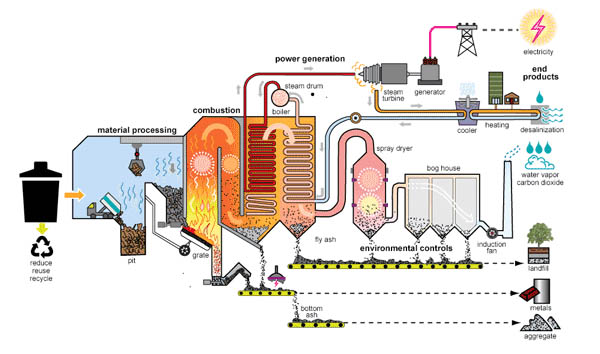

Sharar datti yanzu babbar matsala ce ta duniya. Shara zuwa makamashi shine magani mafi dacewa a halin yanzu. A cikin 'yan shekarun nan, kasashe da yawa da suke da karfin tattalin arziki sun fara mai da hankali kan wannan batun. An kashe kuɗaɗe masu yawa don gina cibiyoyin samar da wutar ƙona shara. Wannan ba wai kawai ya kawo babban ci gaba ga yanayinmu ba. A lokaci guda, ya kawo mana fa'idoji da dama na tattalin arziki.

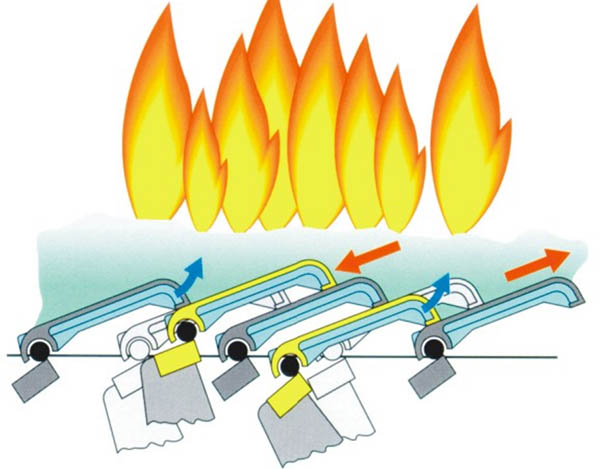

Kamar yadda aka nuna a cikin adadi, sandunan goge suna taka muhimmiyar rawa wajen ƙone sharar gida. A cikin zafin jiki mai tsananin gaske da kuma mawuyacin yanayi, gratean ƙasa mai ƙarancin inganci zai tasiri ƙimar ƙone ƙonewar, kuma rayuwarta ta gajarta sosai. Kuna buƙatar maye gurbin shi sau da yawa sosai.

Koyaya, tare da gogewar gogewar sama da shekaru 10, zamu iya magance muku matsalolin.

Karfe Grade yawanci muna amfani dashi. (Hakanan yana iya zama azaman buƙatunku.)

Abubuwan sunadarai% na ƙarfe GX130CrSi29 (1.4777): EN 10295-2002

|

C |

Si |

Mn |

Ni |

P |

S |

Cr |

Mo |

|

1.2 - 1.4 |

1 - 2.5 |

0.5 - 1 |

max 1 |

max 0.035 |

max 0.03 |

27 - 30 |

max 0.5 |

Abubuwan sunadarai% na ƙarfe GX40CrNiSi27-4 (1.4823): EN 10295-2002

|

C |

Si |

Mn |

Ni |

P |

S |

Cr |

Mo |

|

0.3 - 0,5 |

1 - 2.5 |

max 1.5 |

3 - 6 |

max 0.04 |

max 0.03 |

25 - 28 |

max 0.5 |

Abubuwan sunadarai% na ƙarfe GX40CrNiSi25-20 (1.4848): EN 10295-2002

|

C |

Si |

Mn |

Ni |

P |

S |

Cr |

Mo |

|

0.3 - 0,5 |

1 - 2.5 |

max 2 |

19 - 22 |

max 0.04 |

max 0.03 |

24 - 27 |

max 0.5 |

Abubuwan sunadarai% na ƙarfe GX40CrNiSi25-12 (1.4837): EN 10295-2002

|

C |

Si |

Mn |

Ni |

P |

S |

Cr |

Mo |

|

0.3 - 0,5 |

1 - 2.5 |

max 2 |

11 - 14 |

max 0.04 |

max 0.03 |

24 - 27 |

max 0.5 |

| Kayan aikin inji (ASTM A297 Grade HH) 1.4837 | UTS: Min 75 Ksi / 515 Mpa |

| YS: Min 35 Ksi / 240 Mpa | |

| Tsawowa: a cikin 2 a cikin: Min 10% | |

| Hardness: Min 200 BHN (wurare 3 kan zato) " | |

| Microstructure / Metallography | Tsarin Austenitic galibi wanda ya ƙunshi carbides da aka watse |

| SoundnessTest / X-ray ko UT | RT ta ASTM E446 Mataki na II |

| UT ta ASTM A609 Mataki na II | |

| NDT / LPI ko MPI | MPI kamar yadda ASTM E709 / E125 LEVEL II yake |

| LPI kamar yadda ASTM E165 Level II " | |

| Binciken Kayayyakin Karshe | ASTM A802 Mataki na II |

| Kunshin | Halin ƙarfe ko akwatin katako. |

Babbar Kasuwar Mu

OEM da kamfanonin injiniya

Sharar gida ga tsire-tsire

Kamfanoni masu aiki

Rukunan biomass

Plantsarfin wutar da ke aiki da gawayi

Kamfanonin sabis don ayyukan kulawa

Daban-daban na OEM sandunan sanduna

Da kyau gama sanduna

Tsarin Balaga da Controlaƙƙarfan Ingancin Inganci Shin Me yasa za ku zaɓe mu

Don ƙarin tambayoyi ko tambayoyin fasaha, da fatan za a tuntuɓi Serviceungiyar Sabis na XTJ. Za mu samar da mafi m fasaha bayani da mafi kyau zance bisa ga samfurin.